What is the Product Process Matrix?

Why is the Product Process Matrix Important to Product Management?

Here are a few of the pros and cons of using the matrix:

Advantages

- Invites broader thinking about organizational competence and competitive advantage.

- Enables greater involvement during planning, leading to better alignment among departments and the organization as a whole.

- Provides a pathway to more informed predictions and strategic responses to industry shifts and changes.

- Used to identify business opportunities and guide investment decisions.

Disadvantages

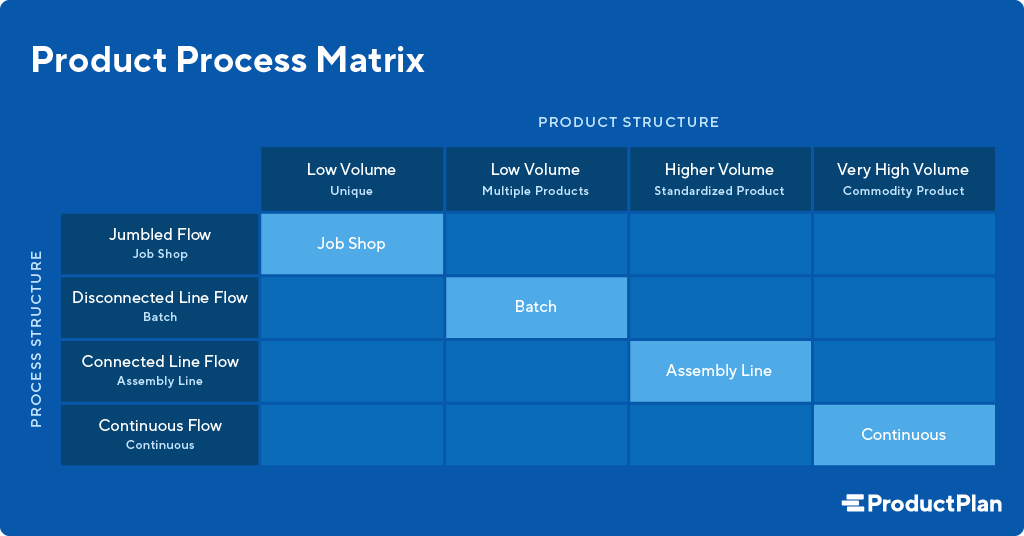

4 Process Stages of the Product Process Matrix

The Hayes-Wheelwright matrix is comprised of four distinct stages. In the first stage, the production process tends to be more flexible with higher associated costs. But by stage four, the production process becomes more standardized, mechanized, automated, far less flexible, and most-effective.

In “Getting to Know the Product-Process Matrix,” Kyle Holland writes:

“The product-process matrix can provide an understanding of the strategic options available, especially when it comes to production efforts. If you fall into a particular part of the quadrant but are using a process that doesn’t align with your placing in the matrix, then it might be time to rethink your process.”

Here are the 4 process stages of the matrix:

1. Job Shop

Tends to be more reactive, focusing on day-to-day issues. Low volume, one-of-a-kind products are the hallmark.

“If you are an organization that falls into the job shop process, it is more than likely that you produce a variety of goods in relatively low production volumes.” (Holland)

2. Batch

The focus here tends to be on productivity enhancement and economies of scale meet standard practice. Competitive differentiation plays a central role. Organizations likely produce multiple products with a low volume.

“A batch process is one that is capable of producing more goods than a job shop, but the volume per good is still not enough to justify dedicated equipment.” (Holland)

3. Assembly Line

At this stage, there are fewer major products but higher volume.

“An assembly line process consists of highly similar goods produced in a repetitive manner. Workstations are set up so that products can pass through them in a sequential order that allows the goods to be produced in the most efficient manner.” (Holland)

4. Continuous Flow

Process and product improvements advance past industry standards and result in a sustainable competitive advantage. At this stage, there’s a high product volume along with high standardization.

“Continuous flow processes require specialized equipment in order to work continuously. This can only be possible when your range of products is extremely limited and you’re required to produce them in an extremely high volume.” (Holland)

Organizations that find the best fit between a chosen product positioning and its related processes achieve the product process matrix’s greatest success.

Related terms: Prioritization, Opportunity Scoring, Weighted Scoring, Action Priority Matrix, Product Development Process.